chair rail molding which side up

Remember how I told you that I was lucky enough to do a guest post over at Perfectly Imperfect? For those of you who didn't get a chance to view it there, here is my tutorial on how to install Chair Rail Moulding. Recently, I designed and completely re-vamped our Master Bedroom. One of my favorite transformations in this room was the addition of our moulding. In this post, I will share how to install your own. This was my first experience with moulding, and I must admit that it was a lot simpler than I had anticipated. Anyone can do this! Here is a shot of the chair rail and picture frame moulding (also known as shadow boxes, or one of the many versions of wainscoting) that my strong and I installed in our Master Bedroom Makeover. Today I will share how we installed the chair rail. It was pretty simp. First, we measured: a) how high we wanted it, and b) how much we needed. In determining the height we wanted, I did a lot of research and looked at a lot of pictures.

I learned that chair rail's initial purpose in history was to prevent walls from being scuffed by chairs (hence the name). In those cases, the height of a person's chair determined the height of the moulding. Nowadays, chair rail is typically installed anywhere from 32"- 40" from the floor. Many go by the thirds rule- measure your ceiling, divide that number in thirds, and install your railing 1/3 of the way up. On a more modern scale, many are installing their chair rail 2/3 of the way or higher up their walls. I absolutely love this look also and think it is perfect for smaller spaces looking for a feeling of comfort, like a nursery or bathroom. Since I am a traditional gal, I installed my chair rail at the height of my French Wingback Chair in our bedroom, which in our case was 40" from the floor at the top of the rail. We have 8' (or 96") tall ceilings, so ours did not follow the 1/3 rule exactly but we love the way it looks. Once you determine the height, you need to b) measure the length.

I simply measured the length of each wall, less the width of doors and windows. You have a few options here. If you really want to keep the project cost as inexpensive as possible, you can simply take that total number of inches and calculate how many pieces of moulding you need by dividing your number of inches by 8, since moulding is typically purchased as 8' long pieces.

cheap beach chairs myrtle beachThis will tell you how many pieces to buy.

buy wheelchair accessoriesKeep in mind though that you will have to use small pieces of your 8' sections in some places in order to use all of it up, which will result in a lot more labor on the caulking side, and a less seamless and perfect look.

baby shower chairs boston In my opinion, it was so worth the extra $ to purchase a little bit more moulding overall to ensure that we could use as large of pieces as possible on each wall.

wood rocking chair outdoor

Next, head off to your fave hardware/ paint store to pick up the goods. I spent far too long than I needed to in Home Depot and Lowes trying to make my decision on what to buy. The selection for actual "chair rail" was minimal in both stores (2 choices) so I decided to take a walk on the wild side and used something else.

office chair ikea ukI went with a casing (intended for doors) that had a different profile from the traditional chair rail.

ikea urban chair paint Chair rail typically begins with the profile flush against the wall, curves out in a design, and then returns back to the wall at the bottom. Since we have a Craftsman style home with very basic door casing and baseboards, I needed something a bit more boxy, while slowly introducing some curves. Here is the best profile shot I could get of the Victorian casing I chose from Lowes.

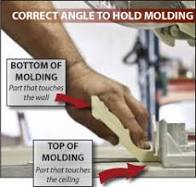

Unlike traditional chair rail, this "chair rail" of ours has an extended profile at the top where it creates a little ledge. The only con I see is that more dusting will be required, but I'm slightly OCD about cleaning anyway so that's not really a problem to me. I love the way that it incorporates a boxy feel (at top) while introducing more classy looking curves at the bottom. So, we picked up our primed casing from Lowes and went home to get cutting. First, my sweets and I took the measurement of our first wall (105") determining that we needed to use one of our 8' long pieces (96"), plus approx 9" of another piece. With our Miter Saw, we (okay, he) placed the first piece of moulding on the saw table standing up with the flat end of the chair rail butted up against the back of the saw, and cut the right end of our first piece at a 45 degree angle, keeping the other (left) end uncut since it would meet up against our door frame. If you have never used a miter saw before, the task may seem daunting but it really is simple.

If you plan on installing a lot of moulding in your home or using it as additions to furniture, cabinets, etc. I highly recommend investing in a miter saw. They do sell small miter boxes for around $10 at hardware stores which in theory will allow you to make the same cuts, but you do the labor manually with a hand saw and will probably wish that you had invested in miter saw after your arm muscles start burning. The next piece of moulding was cut at a 45 degree angle also, but on the reverse side of the saw (by rotating the blade over to the opposite side). rotating the saw to the other side ready for the opposite 45 degree cut This piece would then fit snugly underneath the first cut. To finish this wall, we had one last 45 degree angle cut to make for the inside corner (the same as the first 45 degree cut). Many prefer to cut all of their pieces before installing, but we liked to work wall at a time so that we could adjust the corner cuts accordingly to create a snug and perfect fit.

Here's how we installed the cut moulding. We applied a thin layer of liquid nails (a very strong wood glue) to the back of the moulding. While one of us held the moulding up at the desired height and location on the wall, the other held up a level to make sure it was perfect. Using a pneumatic brad nailer we secured it in place first with as minimal nails as possible. The simplest and most effective way to secure the chair rail in place is to nail directly into a stud (2 x 4). We used a stud finder to locate these while the other continued to hold the moulding in place and then nailed it into the stud. We also nailed on each end. Finally, our first wall looked like this: We finished all of the other walls the same way (making straight 90 degree cuts around door frames and windows). Next, we set the nails so that they were all shallower than the moulding itself. shown on picture frame moulding below, but the same process was done on the chair rail