buy windsor chairs uk

Hear first about our FAMOUS SALES EVENTS!be the first to hear about our Secret Sales including our famous Black Friday Event and Outlet Sales of up to 70% off. Simply enter your email below David Colwell C3 chairs William Warren's stacking Windsor The Friends of the WilsonThe Wilson The Larder Fitzroy Place And Then DesignThe Larder Original BTCCecilCecil Table Lights Stix sofa for Ian Archer Daniel Schofiled's Department Tables The Great Heal's Bodging Race Eden range for Cintique James UKHoltonWingback, Lucan, Aiken Avery barstools for Pinch Katie Walker's Windsor Rocker. Our Man in Shanghai Great Windsor Chair Race 50 chairs for The Wild Rabbit A chair collection for John Lewis Horseshoe Chair by Steuart Padwick A Jubilee Chair for Katie Walker’s Windsor Rocker A bench for the V&A Assembly Room in the Falklands A visit from Koji Katsuragi Spade Chair by Faye Toogood

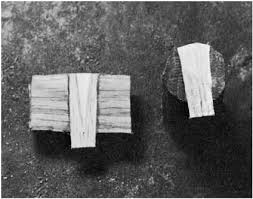

The Achair by David Colwell Log Bench by Chris Eckersley Arden Dining range in Milan Sugawara Educational Foundation, JapanAny experience making or repairing chairs gives you a little bit of insight into how important the joinery is in chairs. And chairmakers have long used socket joints – joints made with a round hole and a round tenon – because they can be made quickly and easily. One problem: these are a rather weak type of joint. That explains why with so many chairs when the glue fails, the socket joint fails and you end up with a loose, wobbly chair (or worse). An examination of Windsor chairs offers insight into overcoming this problem of socket joints. As chair making expert and “Make a Windsor Chair” author Mike Dunbar points out: “Every joint in a handmade Windsor chair incorporates some mechanical feature that holds the join together after the glue has failed . . . the ways Windsor chair makers overcame socket construction’s inherent weakness are truly remarkable.”

The solutions you can find examining Windsor chair joinery include straight wedged joints, locking taper joints, drive fit tenons and tenons in compression. To learn how these types of socket joints work, download this free except from Dunbar’s fascinating book on the subject: “Make a Windsor Chair” by Mike Dunbar is included The Chairmaking Ultimate Collection (which features four books, two DVDs, and eight digital videos). The Windsor style chair is perhaps the most popular chair for those interested in early American furniture. Our collection of museum-quality reproduction Windsor chairs is designed using mid 18th century examples. The chairs are constructed using wedged through tenon construction - using maple, hickory and poplar woods where appropriate to the construction of the chair. Our Windsors are available in a Painted Aged-Crackle Finish or in our Painted Museum Finish. Antique Windsors were painted to blend the mixture of woods found in a period Windsor chair.

He sought shelter in a simple home of one of his peasant subjects, where he came upon a simple chair.

racing game chair xbox 360 The chair seat was made from a single plank of wood. The turned legs were in holes, drilled through the seat and then were locked in place by wooden wedges driven into the top of the leg. The back of the chair consisted of spindles rived from logs. They were glued into holes in the seat and then run into the chair crest or through the chair bow. The King was so impressed with the simplicity and comfort of the chair, that he ordered several made in the same style for Windsor Castle. So a lowly handmade chair, made by the �common man� was now named after a royal castle. The American Windsor chair shares the same basic design and construction traits of its English ancestor. Where the English chair was sometimes made from hardwood throughout, the American chairs had softwood seats, maple turnings and hickory spindles, which made them light, yet very sturdy.

Each region of our country made the same basic style of chairs, but each geographical area seemed to develop its own twist on the basic design. The turnings on Pennsylvania chairs were known for their blunt arrow turnings and sturdy vase legs. The turnings on New England chairs were lighter and more delicate. Knuckle arms and the ears on fan back chairs varied from maker to maker. Bamboo turnings were done in all areas of the country in the 19th century as chair demand exceeded the availability of skilled turners. Since these chairs were made of mixed woods they were usually painted in solid colors. Sometimes the seats were grain painted or the chairs were decorated in the style of the period. Settees, high chairs, rocking chairs, stools and even some Windsor tables were also made by these craftsmen. To find a chair which retains it's �paint history� from the day it was made is a rare occurrence. From the collector's point of view, finding a chair with is original finish intact is very exciting;